3DL materials are less prone to damage than woods, veneers, lacquered surfaces and solid surfaces.

Wear resistance greater than HPL, up to 450 Taber test cycles versus 400 for HPL. Soft, ergonomic shapes and edges that can’t be created with other decorative surfaces. 3DL - Material Intelligence ģDL surfaces wrap five of six panel sides, creating a seamless panel face.What is the difference between hPL 3DL and 3DL?ģDL surfaces wrap five of six panel sides, creating a seamless panel face Soft, ergonomic shapes and edges that can’t be created with other decorative surfaces Wear resistance greater than HPL, up to 450 Taber test cycles versus 400 for HPL 3DL materials are less prone to damage than woods, veneers, lacquered surfaces and solid surfaces. Edges: 3DL is “self-edging” – the fabrication process wraps the material around panel edges. What is designdesign 3DL?ĭesign Matches: 3DL producers publish guides to matches in complementary materials – TFL, HPL, decorative paper foils and edge treatments, as well as peel-and-stick materials.

3dlabprint corsair crack#

Because the surfaces are thermoplastic, impact damage won’t crack 3DL faces.

Finished 3DL components have seamless faces and edges, making them impervious to moisture and bacteria, and very unlikely to delaminate. What are the benefits of 3DL materials?ģDL materials are less prone to damage than woods, veneers, lacquered surfaces and solid surfaces. Seamless Finish Painted to match the color of your truck. Adds over 4" above the truck bed rail of additional storage space. Dual Side Access Convenient access to your truck bed.

3dlabprint corsair series#

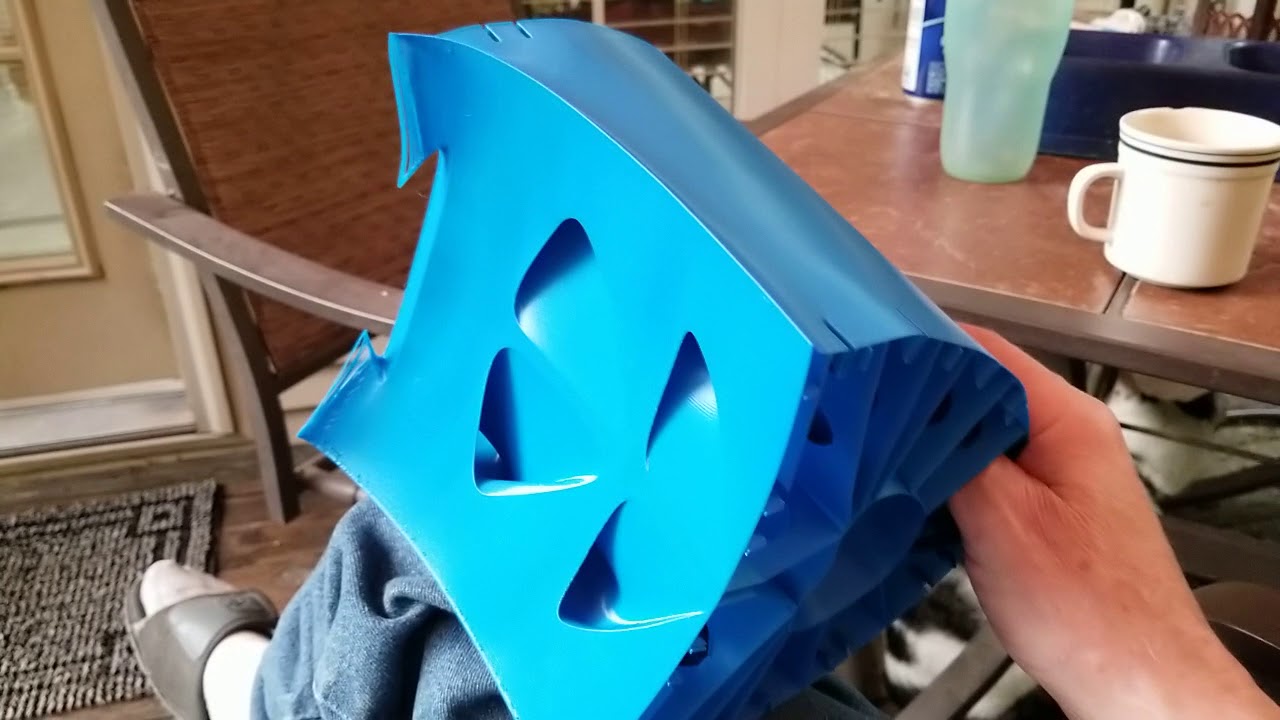

The 3DL Series turns the bed of the truck into an organized and readily accessible tool container that keeps dust and other elements out.

0 kommentar(er)

0 kommentar(er)